Metal Finishing Chart

Metal Finishing Chart - Web machinists use metal surface finishing for protective chemical reactions on metal surfaces and to also beautify them. Premier metal finishing services for high tech commercial. Metal finishes come in many. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Your source for quality metal finishing since 1988! Fabricators, machinists, and metal finishers often use the highly. Web there are several different ways to measure the surface finishes of sheet metal fabricated parts. Web have a project in mind? Choosing the type of metal surface finish to. It’s likely that the actual finishes will vary to some degree from those depicted herein, due to difficulties involved in. Web have a project in mind? Web this guide offers you quality information about surface finish and provides a handy surface roughness chart for better understanding. Web anodize, hardcoat, electropolish, passivation, chem film iridite. Web finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized and relieved. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Web metal surface finish charts are a reference tool used for assuring quality and precision in surface preparation. North america’s largest metal forming, fabricating, welding, and finishing event heads to orange county. Web there are several different ways to measure the surface finishes of sheet metal fabricated parts. Web a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. Web more and more finishing engineers have switched from liquid finishing to powder coating as the way to produce high quality, durable finishes. Fabricators, machinists, and metal finishers often use the highly. Web this guide offers you quality information about surface finish and provides a handy surface roughness chart for better understanding. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Premier metal finishing services for high tech commercial. Web join balluff. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Web a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. Web join balluff at fabtech 2024, orlando fl. Web this metal finish chart is provided as a guideline only. Web machinists use metal. Web this unique chart compares different metal finishes by cost, corrosion resistance, applications and more. Web finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized and relieved. Metal finishes come in many. Web metal surface finish charts are a reference tool used for assuring. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Fabricators, machinists, and metal finishers often use the highly. Web the specification database is an extensive online resource of metal finishing specifications from professional specifications. Web machinists use metal surface finishing for protective chemical reactions on metal surfaces and to also beautify them.. Web the specification database is an extensive online resource of metal finishing specifications from professional specifications. North america’s largest metal forming, fabricating, welding, and finishing event heads to orange county. Web this metal finish chart is provided as a guideline only. Premier metal finishing services for high tech commercial. Cutting commercial keys, i/c core keys, control keys, and. Web a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. Web click here to view our color chart. Web this metal finish chart is provided as a guideline only. There are a variety of. Web more and more finishing engineers have switched from liquid finishing to powder coating as the. Web finishes chart finishes chart nbha bhma materials finishes 3 605 bright brass, clear lacquered 4 606 satin brass, clear lacquered 5 609 satin brass, oxidized and relieved. There are a variety of. Web this metal finish chart is provided as a guideline only. Manufacturers leverage metal finishing solutions to. North america’s largest metal forming, fabricating, welding, and finishing event. Web have a project in mind? Metal finishes come in many. Web there are several different ways to measure the surface finishes of sheet metal fabricated parts. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. In addition to physical properties like strength, ductility. North america’s largest metal forming, fabricating, welding, and finishing event heads to orange county. Web metal finishing charts provide you with detailed information on different treatments, giving you a clear understanding of how different metal finishing methods affect the. Web have a project in mind? Manufacturers leverage metal finishing solutions to. Web more and more finishing engineers have switched from. Premier metal finishing services for high tech commercial. Metal finishes come in many. Web the specification database is an extensive online resource of metal finishing specifications from professional specifications. It’s likely that the actual finishes will vary to some degree from those depicted herein, due to difficulties involved in. Web join balluff at fabtech 2024, orlando fl. Cutting commercial keys, i/c core keys, control keys, and. Premier metal finishing services for high tech commercial. Fabricators, machinists, and metal finishers often use the highly. Web this metal finish chart is provided as a guideline only. Web have a project in mind? Manufacturers leverage metal finishing solutions to. Web there are several different ways to measure the surface finishes of sheet metal fabricated parts. Web metal finishing charts provide you with detailed information on different treatments, giving you a clear understanding of how different metal finishing methods affect the. Web master keying of commercial locks, deadbolts, & cylinders, including interchangeable cores to any multi level system. Web this unique chart compares different metal finishes by cost, corrosion resistance, applications and more. It’s likely that the actual finishes will vary to some degree from those depicted herein, due to difficulties involved in. Web anodize, hardcoat, electropolish, passivation, chem film iridite. Web the specification database is an extensive online resource of metal finishing specifications from professional specifications. Web more and more finishing engineers have switched from liquid finishing to powder coating as the way to produce high quality, durable finishes. Web how do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Choosing the type of metal surface finish to.Metal Surface Finish Chart

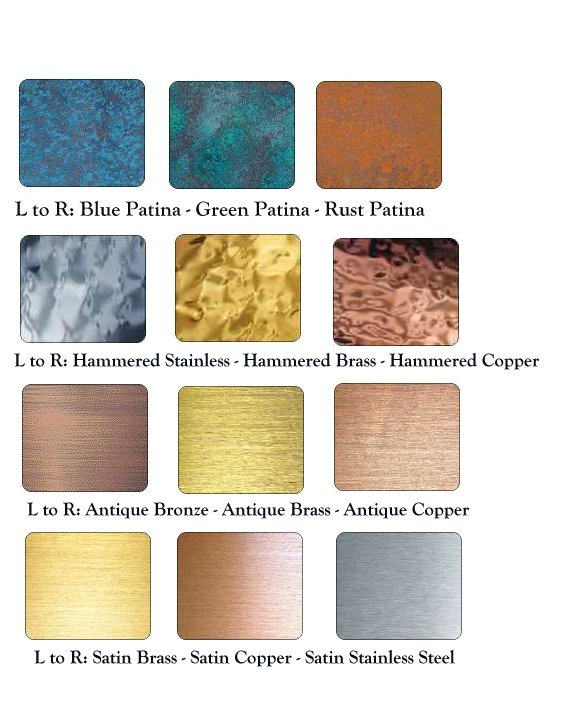

Metal Finish reference guideNewport Brass In the home Pinterest

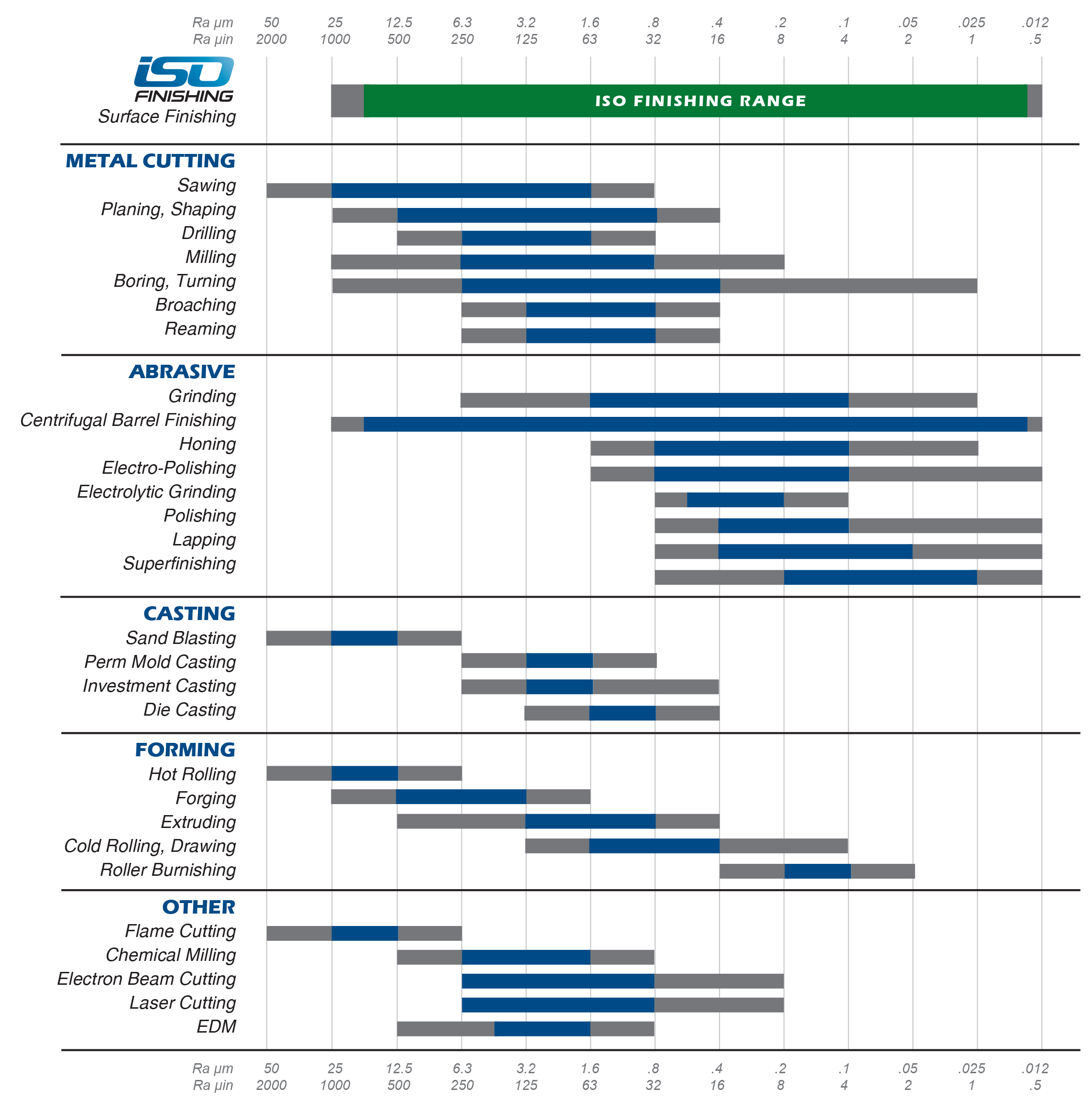

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables

METALS FINISH GUIDE(AB)

Surface Roughness Chart Comparison ISO Finishing

Stainless Steel Sheet and Plate Finishes Euro Steel, SA

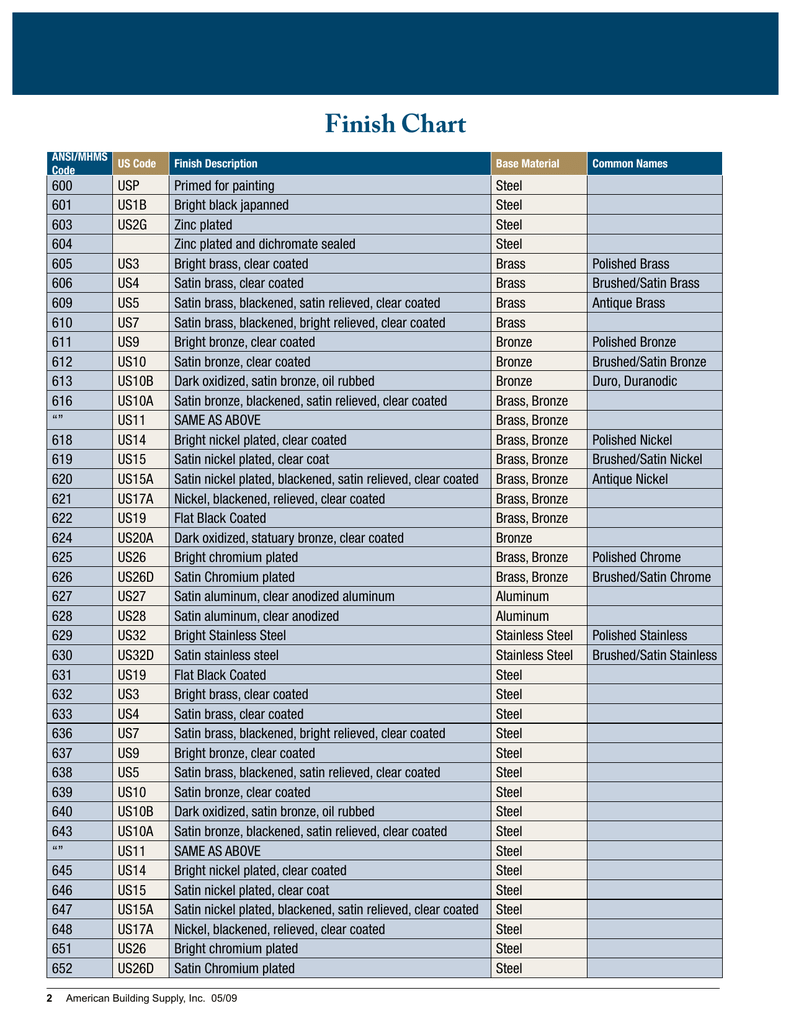

Finish Chart American Building Supply, Inc.

Surface Finish Specification Chart

Steel Finish Chart A Visual Reference of Charts Chart Master

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

In Addition To Physical Properties Like Strength, Ductility.

Web Metal Surface Finish Charts Are A Reference Tool Used For Assuring Quality And Precision In Surface Preparation.

Web Click Here To View Our Color Chart.

Web Join Balluff At Fabtech 2024, Orlando Fl.

Related Post: