Flux Core Welding Settings Chart

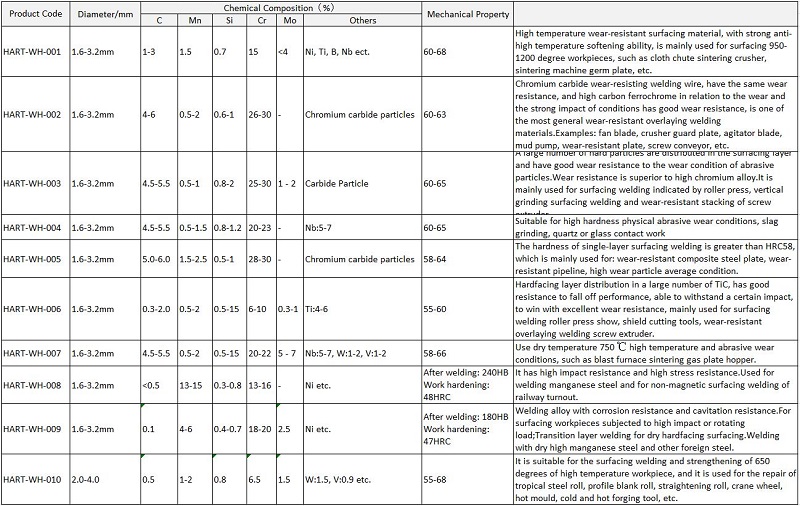

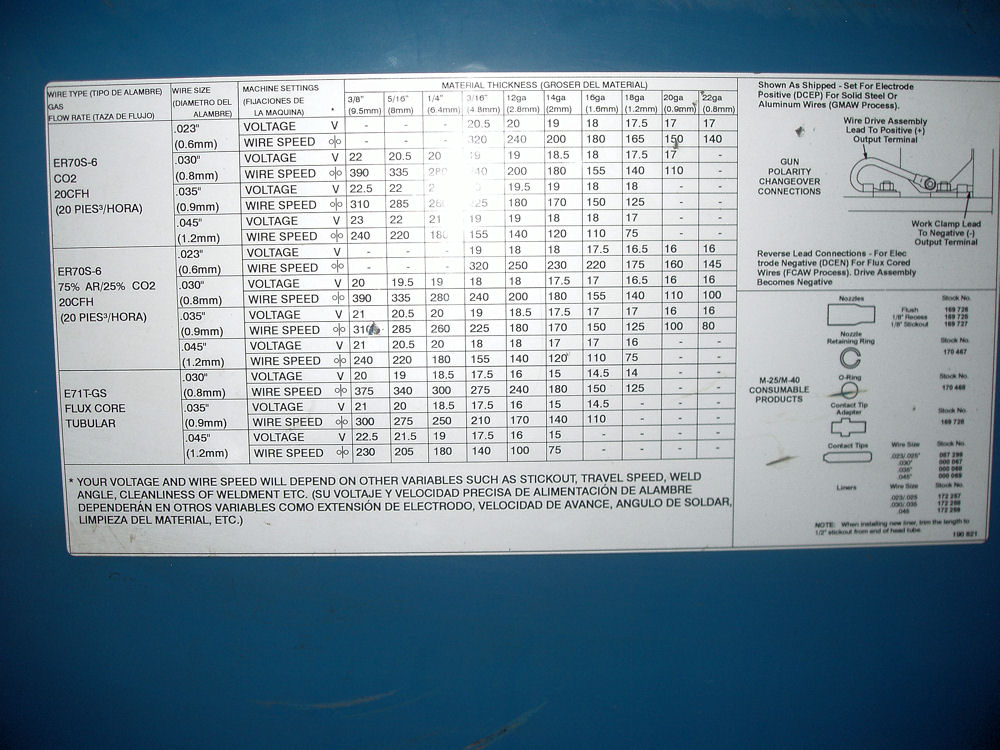

Flux Core Welding Settings Chart - Web comprehending flux core mig welding entails employing the correct wire speed and voltage settings for optimal outcomes. Web how much voltage and amperage a weld requires depends on metal thickness, joint configuration, welding position and wire diameter. There is some nuance to it. For different welding positions and welding types the wire parameters happen to be different every time. Make sure your polarity is correct. This will be good for most jobs up to about ½”. But before using these values, we suggest that you have a decent understanding of your preferred metal. Here's a guide to setting it up. These parameters determine the heat input and the amount of welding wire deposited into the weld. It provides welders with a tested range of amperage settings linked to the wire size used and the material’s thickness. Web settings based on butt welds. Instead, everything you need to deposit a weld comes from a spool of metal wire. In gas metal arc welding (gmaw), you won’t be using a stick electrode or a filler rod. These parameters determine the heat input and the amount of welding wire deposited into the weld. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Here's a guide to setting it up. The lincoln weld pak 140 hd k2514 mig welder is the same as the: For instance, if you want to want to work with a wire diameter of 0.30mm and 9.5mm material thickness, leave the welder o 19 and 340. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Refer to the flux core mig welding wire speed and voltage chart to verify your accurate settings to attain the desired weld bead width, penetration, and overall quality. This will be good for most jobs up to about ½”. Reference charts are available on your power source to help set the correct voltage and wire feed speed based on the wire diameter and material thickness. Web the welding parameters involved in dual shield flux core welding include voltage, amperage, and wire feed speed. However, you will need special. 1/16 flux core wire settings. For instance, if you want to want to work with a wire diameter of 0.30mm and 9.5mm material thickness, leave the welder o 19 and 340. Techniques for optimal 1/16 flux core welding. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. It’s worth knowing. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. Here's a guide to setting it up. In gas metal arc welding (gmaw), you won’t be using a stick electrode or a filler rod. Web settings based on butt welds. Web what material are you welding? Web the welding parameters involved in dual shield flux core welding include voltage, amperage, and wire feed speed. But before using these values, we suggest that you have a decent understanding of your preferred metal. Techniques for optimal 1/16 flux core welding. It provides welders with a tested range of amperage settings linked to the wire size used and the. Make sure your polarity is correct. Techniques for optimal 1/16 flux core welding. Web how much voltage and amperage a weld requires depends on metal thickness, joint configuration, welding position and wire diameter. Web what material are you welding? 1/16 flux core wire settings. Web download the app version of the weld setting calculator for easy reference! Web flux core welding settings chart. These parameters determine the heat input and the amount of welding wire deposited into the weld. In gas metal arc welding (gmaw), you won’t be using a stick electrode or a filler rod. This chart is essential for achieving proper weld. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. 1/16 flux core wire settings. Longevity is recognized worldwide for providing reliable welding, cutting, and power generating equipment. Web how much voltage and amperage a weld requires depends on metal thickness, joint configuration, welding position and. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Web how much voltage and amperage a weld requires depends on metal thickness, joint configuration, welding position and wire diameter. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. The lincoln weld pak 140. Basics of 1/16 flux core wire. Properly adjusting these parameters is crucial for achieving an optimal balance between penetration and deposition rate. Parameters for 1/16 flux core wire. There is some nuance to it. Web what material are you welding? Web settings based on butt welds. Web the flux core welding settings chart provides detailed information about the recommended settings for flux core welding, including wire speed, voltage, and polarity. Web here goes a chart for 0.045 flux core vertical settings depending on several welding positions. Basics of 1/16 flux core wire. This will be good for most jobs up. The lincoln weld pak 140 hd k2514 mig welder is the same as the: It’s worth knowing that lincoln electric sells the 140 mig welder under a few brand names. Web the welding parameters involved in dual shield flux core welding include voltage, amperage, and wire feed speed. Make sure your polarity is correct. But before using these values, we suggest that you have a decent understanding of your preferred metal. Web our 7 tips & tricks for beginner flux core welding 1. Properly adjusting these parameters is crucial for achieving an optimal balance between penetration and deposition rate. For instance, if you want to want to work with a wire diameter of 0.30mm and 9.5mm material thickness, leave the welder o 19 and 340. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to. Longevity is recognized worldwide for providing reliable welding, cutting, and power generating equipment. Instead, everything you need to deposit a weld comes from a spool of metal wire. Reference charts are available on your power source to help set the correct voltage and wire feed speed based on the wire diameter and material thickness. Web download the app version of the weld setting calculator for easy reference! There are many mig setting charts available from manufacturers that all vary. It provides welders with a tested range of amperage settings linked to the wire size used and the material’s thickness. Refer to the flux core mig welding wire speed and voltage chart to verify your accurate settings to attain the desired weld bead width, penetration, and overall quality.Flux Core Welding Settings Chart

What flux core wires to keep on hand? Welding Site

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

Flux Core Welding Settings Chart

MIG FluxCored Welding Calculator Electrical Components

Flux Core Welding Chart

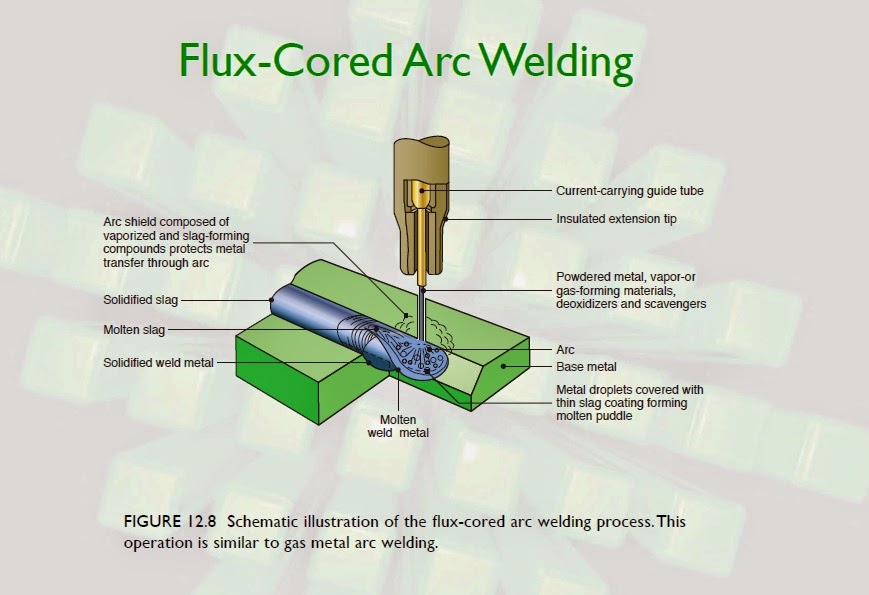

FCAW or Flux Cored Arc Welding Learn Basic Welding Techniques

Flux Core Welding Chart

How To Set Up A Flux Core Welder

Yeswelder Flux 135 Settings Chart

Web Comprehending Flux Core Mig Welding Entails Employing The Correct Wire Speed And Voltage Settings For Optimal Outcomes.

This Chart Is Essential For Achieving Proper Weld.

So That You Know Where Start To Get Yourself A Strong Good Looking Weld.

Joint Design, Fitup, Backup, Position, Bead Size And Stickout May Alter Conditions.

Related Post: