4140 Heat Treat Chart

4140 Heat Treat Chart - Web alro steel is your one stop shop for online metal purchases. Web heat treatment to 845 °c (1555 °f), slow cooling from 755 °c (1390 °f) at a rate of 14 °c (25 °f)/hour to 665 °c (1230 °f), or rapid cooling to 675 °c (1250 °f) for 5 hours isothermal annealing. Web heat treatment involves subjecting a material to controlled heating and cooling processes to achieve specific properties. Other procedures and hardnesses may be available. Hot rolled or thermally treated rectangular sheared plates, circular and sketch plates. Web the heat treatment of 4140 steel typically involves a combination of processes, including annealing, normalizing, quenching, and tempering. Web 1) 4140 is an ok die steel but is not recommended for radical shaped dies such as narrow fullering, crown and so on. Web key properties include: Choose from a vast set of offerings in our metals catalog. The heat treating information shown represents typical procedures and hardnesses for many applications. See individual data sections for more specific information. Choose from a vast set of offerings in our metals catalog. These properties can vary depending on the treatment processes like qt or annealig and normalizing. The following are hardenable grades of alloy steel and the perspective normalizing temperature, annealing temperature and quenching medium table chart. Call us or order online today! Web the heat treatment of 4140 steel typically involves a combination of processes, including annealing, normalizing, quenching, and tempering. 2) fully hardened 4140 ranges from 54 to 59 hrc. These steels are fine grain unless otherwise specified. 4140 tfht flats are readily available, and can be surface ground to tool steel tolerances. Web heat treating common steels temperature and quenching medium chart. For 4140 alloy steel, heat treatment is crucial for optimizing its mechanical characteristics, making it. See individual data sections for more specific information. Web heat treatment to 845 °c (1555 °f), slow cooling from 755 °c (1390 °f) at a rate of 14 °c (25 °f)/hour to 665 °c (1230 °f), or rapid cooling to 675 °c (1250 °f) for. The heat treating information shown represents typical procedures and hardnesses for many applications. See individual data sections for more specific information. Web alro steel is your one stop shop for online metal purchases. Web 4140 is the most commonly used of the high tensile steels with a wide range of applications in automotive, gear and engine construction, crankshafts, steering knuckles,. Web alro steel is your one stop shop for online metal purchases. See individual data sections for more specific information. The heat treating information shown represents typical procedures and hardnesses for many applications. Brinell hardness of around 197. Web heat treating common steels temperature and quenching medium chart. Web alloy steel heat treating normalizing, annealing temperature table chart. Select tempering temperature according to the required mechanical properties (refer to tempering curve). Web alro steel is your one stop shop for online metal purchases. But it should be tempered for any heavy use. Understanding the different heat treatment methods and factors that affect the process is essential for achieving. Web 4140 is the most commonly used of the high tensile steels with a wide range of applications in automotive, gear and engine construction, crankshafts, steering knuckles, connecting rods, spindles, intermediate gears, pump and gear shafts. Web 1) 4140 is an ok die steel but is not recommended for radical shaped dies such as narrow fullering, crown and so on.. These properties can vary depending on the treatment processes like qt or annealig and normalizing. Web heat treatment involves subjecting a material to controlled heating and cooling processes to achieve specific properties. Web key properties include: Web carbon & alloy steels heat treatments. Web heat treating common steels temperature and quenching medium chart. Call us or order online today! Web heat treatment to 845 °c (1555 °f), slow cooling from 755 °c (1390 °f) at a rate of 14 °c (25 °f)/hour to 665 °c (1230 °f), or rapid cooling to 675 °c (1250 °f) for 5 hours isothermal annealing. Web alloy steel heat treating normalizing, annealing temperature table chart. Aisi 4140 alloy. These steels are fine grain unless otherwise specified. See individual data sections for more specific information. *nitrided surface will be higher hardness. Web 4140 is the most commonly used of the high tensile steels with a wide range of applications in automotive, gear and engine construction, crankshafts, steering knuckles, connecting rods, spindles, intermediate gears, pump and gear shafts. Web alro. Call us or order online today! Web alloy steel heat treating normalizing, annealing temperature table chart. 2) fully hardened 4140 ranges from 54 to 59 hrc. Choose from a vast set of offerings in our metals catalog. These parts are roughly 4 diameter and 1.75 thick. The following heat treatment parameters should be used to harden the steel. Aisi 4140 alloy steel is heated at 845°c (1550°f) followed by quenching in oil. 2) fully hardened 4140 ranges from 54 to 59 hrc. Web alloy steel heat treating normalizing, annealing temperature table chart. Assistance with heat treatment should be sought from reputable heat treatment companies. The following heat treatment parameters should be used to harden the steel. Quenching solutions act only through their ability to cool the steel. See individual data sections for more specific information. Web 4140 is the most commonly used of the high tensile steels with a wide range of applications in automotive, gear and engine construction, crankshafts, steering knuckles, connecting rods, spindles, intermediate gears, pump and gear shafts. But it should be tempered for any heavy use. They have no beneficial chemical action on the quenched steel and. So let’s explore the key steps and success factors for 4140 heat treatment. The longer dimension specified is considered the length. Web the heat treatment of 4140 steel typically involves a combination of processes, including annealing, normalizing, quenching, and tempering. The heat treating information shown represents typical procedures and hardnesses for many applications. Assistance with heat treatment should be sought from reputable heat treatment companies. 4140 has a nominal carbon content of.4% and this carbon content will yield a hardness of rc 51 for a 90% martensitic structure (9th edition of the asm material handbook,volume i). 4140 ht can also be surface hardened to increase wear resistance. Web typical analysis is shown in the chart below: Web alro steel is your one stop shop for online metal purchases. Web alloy steel heat treating normalizing, annealing temperature table chart.High Tensile Steel 4140 PDF Annealing (Metallurgy) Heat Treating

Spec 4140 & 4130 Heat Treating Annealing (Metallurgy)

4140 Heat Treat Chart

4140 Heat Treatment Chart

4130 and 4140 Heat Treatments PDF Heat Treating Steel

4140 High Tensile Steel PDF Heat Treating Annealing (Metallurgy)

Quick Reference Guide To Heat Treating PDF Heat Treating Steel

Fatigue curves of heat treated, liquid and ion nitrided AISI 4140 steel

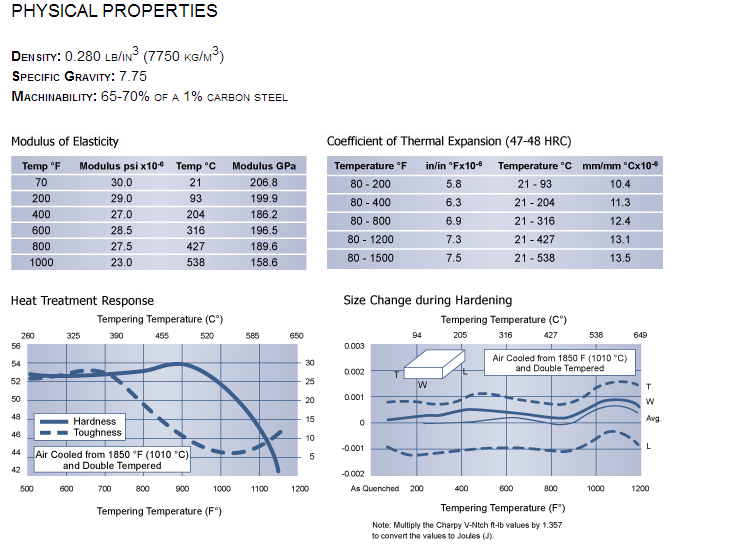

4140 Alloy Steel 1.7225 SCM440 42CrMo4 OTAI Special Steel

4140 heat treat chart Conomo.helpapp.co

Web H Eat Treating 4140 Steel Is A Critical Step In Harnessing Its Exceptional Mechanical Properties.

These Steels Are Fine Grain Unless Otherwise Specified.

Choose From A Vast Set Of Offerings In Our Metals Catalog.

Aisi 4140 Alloy Steel Is Heated At 845°C (1550°F) Followed By Quenching In Oil.

Related Post: